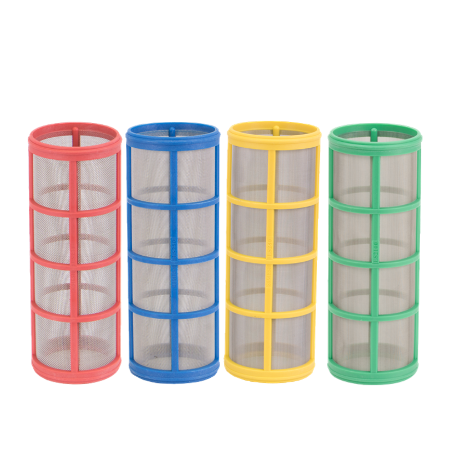

Sprayer Filters

Sprayer filters are indispensable components in any spraying system, whether it's for agricultural applications, industrial processes, or even simple garden spraying. Their primary function is to remove impurities from the liquid being sprayed, ensuring consistent and efficient operation.

Importance of Sprayer Filters:

Preventing Nozzle Clogs: The most critical role of a sprayer filter is to prevent nozzles from becoming clogged. Clogged nozzles result in uneven spray patterns, reduced application accuracy, and wasted chemicals. Protecting Spraying Equipment: Filters protect pumps and other components from damage caused by abrasive particles or debris in the liquid. This extends the lifespan of the spraying equipment. Ensuring Consistent Spray Patterns: By removing impurities, filters ensure that the spray pattern remains consistent, leading to uniform application of the sprayed liquid. Improving Application Accuracy: Accurate application is essential for effective pest control, weed control, and fertilization. Filters contribute to this accuracy by maintaining consistent flow and spray patterns. Reducing Downtime: By preventing clogs and equipment damage, filters minimize downtime for cleaning and repairs. Types of Sprayer Filters:

Suction Filters: These filters are placed on the suction side of the pump to prevent debris from entering the pump. Pressure Filters (Line Filters): These filters are installed in the pressure line between the Control Valve and the Boom Section Valves. Nozzle Filters (Tip Filters): These small filters are located within the nozzle body to provide final filtration before the liquid is sprayed. Strainers: These are a type of filter, that typically are used to remove larger particles.

Key Considerations:

Mesh Size: The mesh size of a filter determines the size of particles it can remove. A higher mesh number indicates a finer filter. Filter Material: Filters are made from various materials, such as stainless steel, nylon, and polypropylene, to withstand different chemicals and operating conditions. Flow Rate: The filter must be able to handle the flow rate of the spraying system. Chemical Compatibility: It is very important that the filter materials are compatible with the chemicals being used. In essence, sprayer filters are vital for maintaining the efficiency, accuracy, and longevity of spraying equipment.

Customer

Reviews

What our customers have to say

Excellent Service

Mark's knowledge of broadacre spraying was outstanding. Hassle free ordering with great communication throughout the entire process. Timely arrival of parts a few days later. Thanks for the help.

Great Quality

I have been purchasing fittings from spraymart for my fabrication business. Cannot fault the quality of the fittings, great service and definitely recommend.

Great Range

Great range of products that suit my needs. We are regularly in need of BSP & NPT fittings and are really happy with the product, great service.

Great Service

Very easy to use website, convenient for us because I can continue to get work done around the farm whilst my parts are delivered to my door. Mark and the team have been great.

Thankyou

Spraymart got me out of trouble as I was in urgent need of some camlocks. Easy ordering process, good to know you guys are there, will be ordering again. Thanks